Over the weekend I finished up the schematic for the nRF24LE1 programmer. Here's a screenshot:

Monday, February 27, 2017

Thursday, February 23, 2017

First KiCad project

A couple of years ago I built a set of boards using the Nordic Semiconductor nRF24LE1 radio chip. These boards are designed to fit snugly into a Compact Flash card case. For programming and debugging it plugs into a standard PCB edge connector. Here's a photo of an incomplete board (this one was damaged during assembly).

A couple of years ago I built a set of boards using the Nordic Semiconductor nRF24LE1 radio chip. These boards are designed to fit snugly into a Compact Flash card case. For programming and debugging it plugs into a standard PCB edge connector. Here's a photo of an incomplete board (this one was damaged during assembly).When I started prototyping this project I used a nRF24LE1 breakout board plugged into a solderless breadboard. To program it I used an FTDI FT232R breakout board plugged into the same breadboard and a custom Linux program. Later, when I had completed radio boards, I used a commercially-available cable that has a 2x13 PCB edge connector on one end and a pin header socket on the other to connect the radio board to the solderless breadboard. The photo below shows both the breakout board and the radio board plugged in at the same time, which of course I wouldn't do in real life.

This worked well during initial development and testing, but the breadboard jumper wires tend to come loose with use (two loose wires are visible in this pic). It's also occupying one of my breadboards for which I have other uses. Since there is actually very little circuitry required to support the FT232R I decided a dedicated programmer board would make an excellent first KiCad project.

Thursday, February 2, 2017

I'm expanding!

By this I mean I'm expanding the scope of this blog, not my waistline.

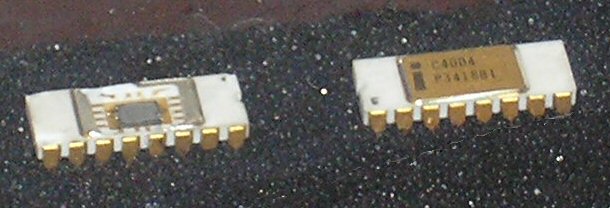

Rather than being solely about my exploration of the Intel 4004 CPU and peripherals, I'm going to include some of my other electronic tinkerings. I'll be tagging the i4004 stuff with an appropriate label, my work with KiCad with another, etc.

I expect this will mean more frequent updating, though as a hobby it will still be dependent on what I find time to work on.

Rather than being solely about my exploration of the Intel 4004 CPU and peripherals, I'm going to include some of my other electronic tinkerings. I'll be tagging the i4004 stuff with an appropriate label, my work with KiCad with another, etc.

I expect this will mean more frequent updating, though as a hobby it will still be dependent on what I find time to work on.

Wednesday, February 1, 2017

A very tight fit

I spent a few hours hunting around for a socket that would accept a row of pins on 2.0 mm centers. There are quite a few of them, but most are designed to accept small square pins, perhaps as wide as 0.66 mm. The pins on the Vacuum Fluorescent Display are 0.7 ±0.12 mm wide and only 0.18 mm thick. This would be trivial if I wanted to solder it directly to a PCB, but I'm not in a position to know what I need in the way of a final PCB yet, and I don't want to risk damaging the VFD by trying to removing it from a PCB.

I think I finally found one possibility: the Mill-Max 8114 series. This is a single-contact pin receptacle able to accept a pin up to 0.86 mm wide, while only being 1.65 mm wide itself. That would leave a 0.35 mm gap between pins. Not terribly wide, but wide enough to fit some sort of insulator between, if need be, to maintain spacing. Maybe a bit of heat-shrink tubing over each one? I'd hope that the centering action of the VFD's pins would make this unnecessary.

A second option is to simply solder some wires to the pins and plug them into the solderless breadboard for testing. The only bit that seems critical is the pin is connected to an on-display oscillator, which requires an RC circuit that needs to be connected close to the pin. For this I'd simply solder the resistor and capacitor directly to the oscillator pin.

I think I finally found one possibility: the Mill-Max 8114 series. This is a single-contact pin receptacle able to accept a pin up to 0.86 mm wide, while only being 1.65 mm wide itself. That would leave a 0.35 mm gap between pins. Not terribly wide, but wide enough to fit some sort of insulator between, if need be, to maintain spacing. Maybe a bit of heat-shrink tubing over each one? I'd hope that the centering action of the VFD's pins would make this unnecessary.

A second option is to simply solder some wires to the pins and plug them into the solderless breadboard for testing. The only bit that seems critical is the pin is connected to an on-display oscillator, which requires an RC circuit that needs to be connected close to the pin. For this I'd simply solder the resistor and capacitor directly to the oscillator pin.

Subscribe to:

Posts (Atom)